Soil mechanics is fundamental to retaining wall design, directly impacting structural integrity, safety, and long-term performance. It governs the complex interplay between active and passive pressures, influencing wall stability and dimensioning. Understanding soil behavior, including cohesive soil characteristics and hydrostatic pressure effects, enables engineers to optimize designs for diverse site conditions. Proper application of soil mechanics principles leads to improved structural integrity, enhanced safety measures, and cost-effective construction practices. It allows for the development of ideal design solutions that incorporate geotextile reinforcement techniques and effective drainage systems. A thorough grasp of soil mechanics guarantees retaining walls withstand forces efficiently while maximizing usable space and preventing erosion.

Table of Contents

ToggleWalls Contractor Highlights

- Soil mechanics determine lateral earth pressures, crucial for optimizing wall dimensions and reinforcement.

- Understanding active and passive pressures ensures cost-effective and stable retaining wall designs.

- Cohesive soil characteristics influence complex pressure distributions, affecting long-term wall performance.

- Proper soil analysis helps predict and mitigate potential failure modes, enhancing safety and structural integrity.

- Soil mechanics principles enable tailored designs for diverse conditions, maximizing efficiency and minimizing maintenance costs.

Soil Pressure Distribution Patterns

Soil pressure distribution patterns are critical in retaining wall design, with the interplay between active and passive pressures forming the foundation of structural stability calculations. Retaining wall functions include preventing erosion and creating usable areas on properties, making proper design essential for long-term performance.

Cohesive soil considerations introduce additional complexities, as these materials exhibit time-dependent behavior and varying strength characteristics based on moisture content and loading history. Hydrostatic pressure effects must also be carefully accounted for, as water accumulation behind a retaining wall can markedly alter the pressure distribution and potentially lead to structural failure if not properly addressed through drainage systems or increased wall strength.

Active vs. Passive Pressure

When designing retaining walls, understanding the distribution of soil pressure is essential. Two critical concepts in this field are active and passive pressure, which play pivotal roles in determining the stability and effectiveness of retaining structures.

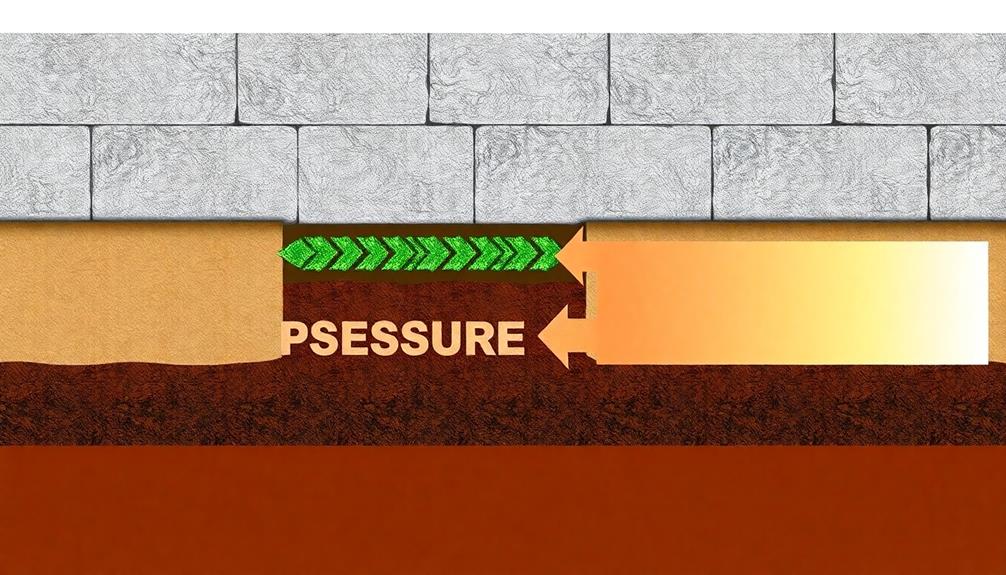

Active pressure occurs when the wall moves away from the soil, allowing the earth to expand horizontally. This scenario typically results in lower pressure on the wall, as the soil assumes its natural angle of repose. Conversely, passive pressure develops when the wall moves towards the soil, compressing it and generating markedly higher resistance.

Engineers and geotechnical specialists must carefully consider these pressure states when calculating the forces acting on retaining walls. The active pressure state is generally the governing condition for design, as it represents the minimum force required to maintain equilibrium. However, passive pressure becomes indispensable in situations where additional resistance is needed, such as in anchored walls or when considering sliding stability. By precisely evaluating both active and passive pressure scenarios, designers can create retaining structures that effectively balance safety, efficiency, and cost-effectiveness, ensuring long-term stability and performance in diverse soil conditions and environmental settings.

Cohesive Soil Considerations

Delving into cohesive soil considerations, engineers must account for unique pressure distribution patterns that differ noticeably from those observed in granular soils. Cohesive soils, characterized by their fine-grained composition and ability to retain water, exhibit complex behavior under loading conditions. This complexity manifests in non-linear pressure distributions along retaining walls, necessitating a more meticulous approach to design and analysis.

In cohesive soils, the pressure distribution is influenced by factors such as soil plasticity, moisture content, and consolidation history. Unlike granular soils, where pressure increases linearly with depth, cohesive soils may display pressure bulbs or zones of increased stress concentration. These variations can dramatically impact the stability and performance of retaining structures.

Engineers must carefully consider the potential for long-term consolidation and creep in cohesive soils, as these processes can lead to changes in pressure distribution over time. Additionally, the presence of clay minerals in cohesive soils can affect their shear strength and compressibility, further complicating the prediction of soil-structure interaction. By thoroughly understanding these cohesive soil characteristics, designers can develop more precise and dependable retaining wall systems that withstand the test of time and safeguard the surrounding infrastructure.

Hydrostatic Pressure Effects

How does hydrostatic pressure influence soil pressure distribution patterns in retaining wall design? The presence of water in soil substantially alters the pressure exerted on retaining structures, necessitating careful consideration in engineering calculations. As water accumulates behind a retaining wall, it introduces additional lateral forces that can compromise the wall's stability if not properly accounted for.

The hydrostatic pressure distribution follows a triangular pattern, increasing linearly with depth. This pressure acts uniformly across the wall's surface, independent of soil properties. When combined with the existing soil pressure, it creates a compound force that must be resisted by the retaining structure.

Engineers must incorporate drainage systems, such as weep holes or perforated pipes, to alleviate this pressure and prevent water accumulation. Additionally, the presence of water can reduce soil strength, particularly in cohesive soils, potentially leading to increased lateral earth pressures. By understanding these hydrostatic effects, designers can develop more robust and efficient retaining wall systems that effectively manage both soil and water pressures, ensuring long-term stability and performance for our community's infrastructure projects.

Benefits

The application of soil mechanics principles in retaining wall design yields a multitude of benefits that greatly enhance overall project outcomes. By incorporating advanced soil pressure distribution analysis, engineers can achieve improved structural integrity and implement enhanced safety measures, resulting in more resilient and reliable retaining structures.

Boulder retaining walls offer a natural and long-lasting solution that can effectively prevent erosion and create usable areas on a property. In addition, this approach facilitates cost-effective construction practices and enables the development of ideal design solutions, allowing for efficient resource utilization while meeting or exceeding performance requirements.

Improved Structural Integrity

Incorporating soil mechanics principles into retaining wall design greatly enhances structural integrity. By thoroughly analyzing soil properties, engineers can accurately determine the lateral earth pressures exerted on the wall, enabling them to design structures that effectively resist these forces. This in-depth approach considers factors such as soil type, moisture content, and compaction levels, ensuring that the retaining wall is tailored to the specific site conditions.

The integration of soil mechanics allows for the optimization of wall dimensions, reinforcement placement, and drainage systems. By understanding the soil's shear strength, compressibility, and permeability, designers can select appropriate materials and construction techniques that minimize the risk of failure. This results in retaining walls that not only meet safety standards but also exhibit superior long-term performance.

Additionally, the application of soil mechanics principles facilitates the prediction of potential settlement and deformation, enabling engineers to implement preventive measures. This proactive approach drastically reduces the likelihood of structural issues, such as cracking, tilting, or collapse, which could compromise the wall's integrity and functionality. Ultimately, the incorporation of soil mechanics in retaining wall design leads to more reliable, durable, and cost-effective structures that can withstand the test of time and environmental pressures.

Enhanced Safety Measures

Three key benefits of enhanced safety measures in retaining wall design stem from the incorporation of soil mechanics principles. First, a thorough understanding of soil behavior allows engineers to accurately predict and mitigate potential failure modes, greatly reducing the risk of structural collapse. This knowledge enables the implementation of robust design features that account for varying soil conditions, water pressures, and seismic activities, ensuring the long-term stability of the retaining wall.

Secondly, soil mechanics informs the selection of appropriate drainage systems, preventing the buildup of hydrostatic pressure behind the wall. By effectively managing water flow, these systems minimize the likelihood of soil erosion and structural damage, thereby extending the wall's lifespan and maintaining its integrity over time.

Lastly, soil mechanics principles guide the development of monitoring protocols and maintenance schedules. These measures allow for early detection of potential issues, such as excessive soil settlement or wall movement, enabling timely interventions to prevent catastrophic failures. By integrating these safety measures, retaining wall designs not only meet regulatory standards but also provide peace of mind to property owners and surrounding communities, fostering a sense of security and belonging.

Cost-Effective Construction Practices

Cost-effective construction practices in retaining wall design, informed by soil mechanics principles, offer significant benefits to both contractors and project owners. By leveraging a thorough understanding of soil behavior, engineers can optimize material usage, reduce labor costs, and minimize long-term maintenance requirements. These practices not only enhance project efficiency but also contribute to sustainability efforts within the construction industry.

Implementing cost-effective strategies involves:

- Utilizing locally sourced materials to reduce transportation costs and carbon footprint

- Employing advanced geotechnical analysis techniques to optimize wall dimensions and reinforcement

- Incorporating modular construction methods to expedite on-site assembly and reduce labor expenses

Optimal Design Solutions

Numerous benefits arise from implementing preferred design solutions in retaining wall construction, grounded in soil mechanics principles. These ideal designs enhance structural integrity, longevity, and overall performance while minimizing environmental impact and maintenance requirements. By incorporating advanced soil analysis techniques and innovative materials, engineers can create retaining walls that effectively resist lateral earth pressures, mitigate water-related issues, and adapt to various soil conditions.

One key advantage of ideal design solutions is the ability to tailor retaining walls to specific site characteristics, ensuring maximum efficiency and stability. This approach often leads to reduced material usage, lower construction costs, and improved aesthetics. In addition, by leveraging cutting-edge computational models and simulation tools, designers can accurately predict wall behavior under diverse loading scenarios, enabling proactive measures to prevent potential failures.

The integration of sustainable practices, such as the use of recycled materials or green engineering techniques, not only enhances environmental stewardship but also contributes to long-term cost savings and improved public perception. Ultimately, the implementation of ideal design solutions in retaining wall construction results in safer, more reliable structures that meet the evolving needs of urban development and infrastructure projects.

Geotextile Reinforcement Techniques

Geotextile reinforcement techniques have revolutionized retaining wall design, offering enhanced stability and cost-effective solutions. These techniques involve the strategic incorporation of synthetic materials into soil structures, leveraging their tensile strength to improve overall wall performance. The following table outlines key aspects of geotextile reinforcement, including types, installation methods, and performance considerations:

| Geotextile Type | Installation Method | Performance Consideration |

|---|---|---|

| Woven | Horizontal Layering | Tensile Strength |

| Non-Woven | Wrap-Around Facing | Drainage Capability |

| Geogrids | Anchor Systems | Long-Term Creep Resistance |

Geotextile Types and Properties

Three primary types of geotextiles are commonly used in retaining wall reinforcement: woven, nonwoven, and knitted fabrics. Each type possesses unique properties that make it suitable for specific applications in soil mechanics and retaining wall design.

Woven geotextiles, characterized by their high tensile strength and low elongation, are ideal for applications requiring separation and reinforcement. Nonwoven geotextiles excel in filtration and drainage due to their high permeability and soil retention capabilities. Knitted geotextiles, though less common, offer a balance of strength and flexibility.

When selecting geotextiles for retaining wall projects, engineers consider several key properties:

- Tensile strength: The ability to withstand tension forces

- Permeability: The rate at which water can pass through the fabric

- Soil retention: The capacity to prevent soil particles from passing through

Understanding these properties allows designers to create robust, long-lasting retaining wall structures that effectively manage soil pressures and water drainage. By incorporating geotextiles into retaining wall designs, engineers can markedly enhance the stability and longevity of these critical infrastructure elements, ensuring the safety and reliability of our built environment for years to come.

Installation and Placement Techniques

Successful implementation of geotextile reinforcement in retaining wall construction hinges on proper installation and placement techniques. The process begins with meticulous site preparation, guaranteeing a level and compacted foundation. Geotextile layers are then carefully rolled out horizontally, with precise overlapping at the seams to prevent soil intrusion. It is indispensable to maintain proper tension during placement to eliminate wrinkles and guarantee uniform stress distribution.

As each layer is installed, backfill material is placed and compacted in lifts, typically ranging from 6 to 12 inches in thickness. This iterative process continues until the desired wall height is achieved.

Special attention must be paid to the connection between the geotextile and the facing elements, whether they are precast concrete panels, modular blocks, or wire mesh. These connections are critical for transferring loads and maintaining the integrity of the reinforced soil mass.

Drainage considerations are paramount, with proper placement of gravel layers and perforated pipes to manage water accumulation. Quality control measures, including on-site testing and inspection, are essential throughout the installation process to verify compliance with design specifications and confirm long-term performance of the retaining wall system.

Performance and Durability Considerations

Considering the long-term viability of geotextile-reinforced retaining walls, performance and durability factors play a key role in their design and implementation. These structures must withstand various environmental stresses, including soil pressure, water infiltration, and potential chemical degradation. To guarantee optimal performance, engineers must carefully evaluate the geotextile's tensile strength, creep resistance, and UV stability.

Additionally, the interaction between the geotextile and surrounding soil is pivotal for maintaining wall integrity over time.

Key considerations for enhancing the performance and durability of geotextile-reinforced retaining walls include:

- Proper material selection based on site-specific conditions and project requirements

- Accurate assessment of long-term creep behavior and stress distribution within the reinforced soil mass

- Implementation of effective drainage systems to mitigate hydrostatic pressure and prevent soil erosion

Walls Contractor FAQ

How Deep Should the Foundation of a Retaining Wall Be?

The foundation depth of a retaining wall depends on several factors, including soil conditions, wall height, and local building codes. Generally, it should be at least 1/3 of the wall's height or below the frost line, whichever is greater.

What Are the Signs of a Failing Retaining Wall?

Signs of a failing retaining wall include visible cracks, bulging or leaning, soil erosion behind the wall, water seepage, and separation from adjacent structures. Regular inspections can help identify these issues early, ensuring the safety of your property and community.

Can Retaining Walls Be Built on Clay Soil?

Retaining walls can be constructed on clay soil, but special considerations are pivotal. Our team recommends thorough soil testing, proper drainage systems, and potentially reinforced designs to guarantee stability and longevity for your project's unique clay conditions.

How Often Should Retaining Walls Be Inspected for Maintenance?

Retaining walls should be inspected annually for ideal maintenance. However, more frequent checks may be necessary in areas with extreme weather or soil conditions. Regular inspections guarantee the wall's stability and longevity, protecting our shared spaces and investments.

What Is the Maximum Height for a DIY Retaining Wall Project?

For DIY retaining wall projects, it's generally recommended to limit the height to 3-4 feet. Anything taller requires professional engineering and may need permits. Always check local building codes and consult experts for your specific situation.